COMPANY

John Franzone Jr. was born in 1919. He was the son of immigrants; his mother, Frances from Scotland and his father, Giovanni (also called John) a builder from Sicily. They lived a comfortable life in Bear Mountain, NY, a relatively rural area north of New York City. It was here that John developed a deep respect and connection with nature. He spent a great deal of time camping, fishing, hiking, and foraging. Even as a child he already had a fascination for invention and adventure. He enjoyed building canoes, fishing rods, and tents that he used regularly to explore his surroundings.

Unfortunately, like many people at this point in history, the Franzone family was economically devastated when the stock market crashed in 1929, spurring the Great Depression and widespread financial ruin across the county. Giovanni was forced to move his family to New York City in search of work. The squalor, rampant poverty, and overcrowding of their new living accommodations was a far cry to the open nature of Bear Mountain. Shortly after moving to the city, John’s mother became very ill, and without money for medical treatment she quickly passed.

John’s grief over the loss of his mother coupled with the unhappiness in the crowded city led him to an interest in airplanes. This relatively new technology allowed him to focus his inquisitive mind and offered an escape from his problems. John was fortunate enough to gain admission to an aviation trade school where he excelled in flying and learning aircraft mechanics. He would continue to fly for nearly the rest of his life, a welcome distraction and adventure from the day to day.

After his graduation from the trade school, he packed his meager belongings and left for Baltimore, Maryland. There he found work with the then booming airplane manufacturer, Glenn L. Martin Company. During this time WWII had begun. John had hoped to fly planes for the war effort and applied to the Army Air Corp, but was denied based on his health. Subsequently he remained at the Glenn L. Martin Company while they transitioned to building aircrafts for the US military.

It was during this period of war that John met his future wife, Madelaine Neutzel, a young secretary employed at the Glenn L. Martin Company. They would go on to have three children and a marriage lasting 72 years. During this time “PLASTIC”, a product in its infancy, was beginning to be used in aviation. John became fascinated with the material, having never been introduced to it before. He quickly saw all the possibilities and potential uses. John, his brother-in-law, and a few more close friends all began experimenting with plastics and they were able to eventually grow their experiments into a part time business. In 1953 they left Glen L. Martin Company and established Fawn Plastics Incorporated. Their business steadily grew and expanded over the years. John’s business acumen and inventive mind sharpened as well and he eventually bought out his original partners to be the sole owner of Fawn.

During his leadership at Fawn, he expanded the company’s directions further than he had ever imagined with his inventive spirit always propelling him to new tinkering and products. John worked on major projects for the world-renowned John Hopkins Hospital, developing several plastic pieces to help doctors better perform open heart surgery. He also worked with National Geographic to help make globes more accurate. John also designed Fawn’s own brand of TV antennae, developed a way to mold aircraft panels for fighter jets that jets that met their strict standards, as well as countless other design applications and developments. He always prided himself making his products the right way, never making a promise he couldn’t deliver, and always going out of his way to find a solution for his customers.

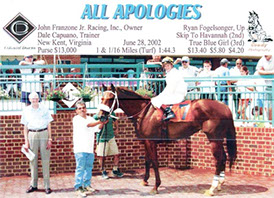

John retired in 1985 and passed on the business to his only son, John B. Franzone. Retirement didn’t agree with the adventurous John and he spent a great deal of time flying and traveling. Only a few years after his retirement, he purchased a farm in Bel Air, Maryland and began breeding racehorses. His passion for learning and inventive spirit didn’t cease in old age and he continued to breed horses, tinker on new inventions, and take frequent excursions and road trips until his death in 2013 at the age of 93. His wife, Madelaine, died only two weeks later.

Today under the direction of John B. Franzone, Fawn continues to operate remembering the key principles instilled by John. Innovative thinking, unsurpassed quality, and customer satisfaction are never compromised at Fawn Industries. Fawn, not unlike John, had humble beginnings but has transformed into a competitive global plastics supplier. With our long history of experience and steady growth we strive to enhance John’s legacy and always go above the standard of excellence.

Fawn Plastics on York Road (MD).

John hiking Bear Mountain.

John standing outside of his Aviation Trade School.

John & fellow employees of Glenn L. Martin Company.

John, age 83, with his winning horse.

John and family with their winning horse.

Fawn employees at Fawn Plastics' first brick-and- mortar operation.

John's horse farm, Flying High Farm.

One of John's planes.

John and family friends.

John's wife, Madelaine and children (left to right) Diane, Paige, & John B.

Fawn's manufacturing facility in Middlesex, NC.

John, age 9, in a canoe he built in Bear Mountain, New York.

John and a co-worker in a plane at Glenn L. Martin company.

John, age 15, in a tent he built.

John shortly after his marriage to Madelaine.

John's wife Madelaine.

16 - 17

<

>

The Family History of Fawn